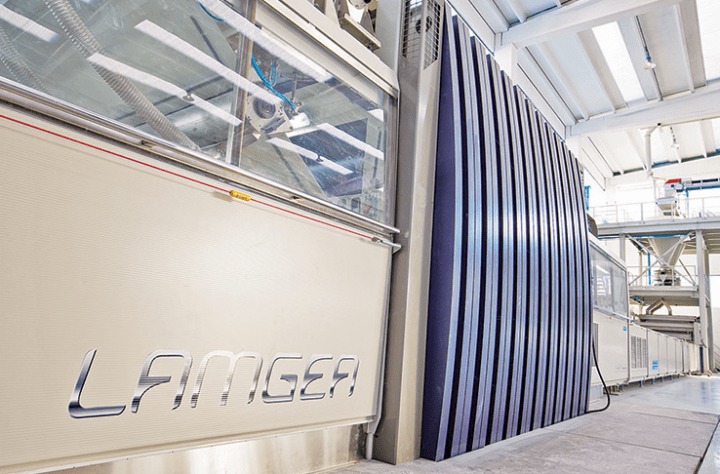

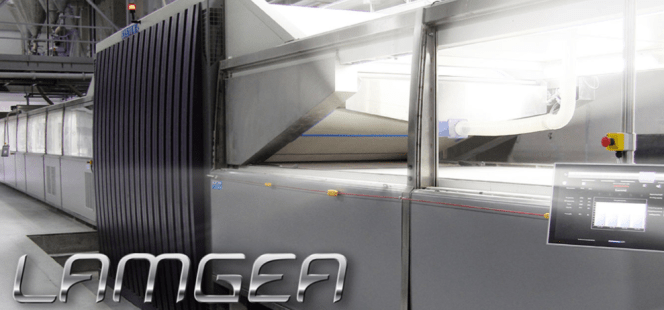

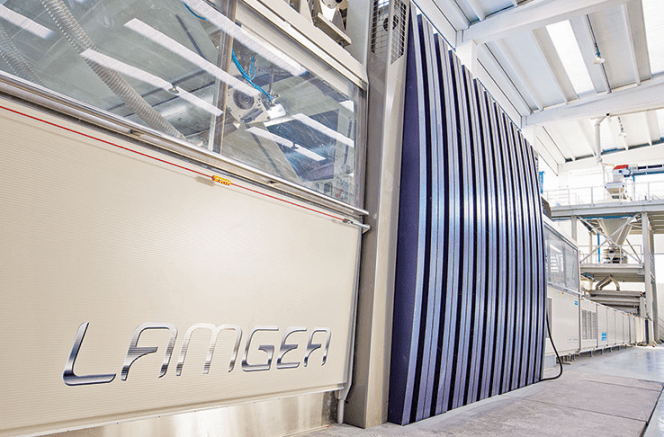

The Marco Polo group, one of China’s largest ceramic tile producers, has installed a Lamgea plant from System Ceramics for the production of 1,200 by 2,400mm, and 1,600 by 3,200mm ceramic slabs in thicknesses ranging from 6 to 12mm.

The Marco Polo group, one of China’s largest ceramic tile producers, has installed a Lamgea plant from System Ceramics for the production of 1,200 by 2,400mm, and 1,600 by 3,200mm ceramic slabs in thicknesses ranging from 6 to 12mm.

The line will be installed in the group’s new factory in the southern province of Jiangxi. Along with Lamgea, the flagship industrial process developed by System Ceramics consisting of an innovative mouldless press for the production of large slabs and panels, the Chinese group will also install three Creadigit BS digital printers. These single-pass inkjet printers are equipped with electronic processing that enables them to print at high speed and create highly realistic images of all kinds with a graphic surface area of up to 200 sq. metres, making every slab unique.

This order demonstrates the importance of cutting-edge technologies capable of guaranteeing unique advantages and high levels of performance within the production process. It also confirms the Italian company as a preferred technological partner for the Asian market, where System China, the subsidiary set up in 2000 in Suzhou, provides efficient customer service through local technicians.

The Marco Polo group is based in Dong Guang and has several factories in China; with a total annual production of over 200 million sq. metres. In 2016 it established a presence in the USA with American Wonder Porcelain based in Tennessee. System Ceramics supplied digital decoration, storage, AGV handling, and packaging solutions for the AWP production plant which came into operation in 2017.

Also from System; Multiflex is an advanced packaging machine designed to be able to pack ceramic tiles of various sizes using neutral or pre-printed carton sheets. Starting from the neutral flat sheet, the machine creates a box by adapting the packaging according to the stack of tiles, so as to manage any variation in terms of calibre and stack height. The material used to obtain the necessary strips comes in a standard 1,200 by 1,200mm size, and is subsequently cut to create a totally tailored package, increasing the level of freedom in the creation of ceramic packaging.

The machine then makes the wrapping, creating a frame around the material, which can reach sizes up to 1,200 by 1,800mm. The control panel is fitted with a latest generation industrial Copilot PC with 15.6” full HD touch-screen and intuitive management software.

In terms of performance, Multiflex is able to produce up to 10 boxes a minute with a considerable saving of cardboard (up to 80% depending on the size). This is a fundamental aspect with regards to environmental protection and energy saving. Furthermore, the positioning of the 4 carton storage units can be managed in a single row (right or left) or on both sides (2 on the right and 2 on the left).

With Multiflex, boxes can be formed for different sizes with extremely rapid size change operations, while the graphics printed in real time on the package can be customised.

More at: https://www.systemceramics.com/en