Following the energy crisis in 1980, many saving technologies have been investigated with attempts to implement them into various industries, one of them is the field of ceramic production.

Following the energy crisis in 1980, many saving technologies have been investigated with attempts to implement them into various industries, one of them is the field of ceramic production. In order to comply with energy saving trends and environmental issues, the European ceramic industry sector has developed energy efficient systems which reduced significantly production time and costs and reduced total energy consumption. The last achievement is of great importance as the energy consumption of the ceramic process accounts for a significant percentage of the total production costs.

More precisely, the firing stage consumes the highest amount of energy during the whole ceramic production process. The use of roller kilns, fired by natural gas, involves a loss of 50% of the input energy via the flue gas and the cooling gas exhausts.

This review paper briefly describes the production process of the different ceramic products, with a focus on the ceramic sector in Europe. Due to the limited on waste heat recovery in the ceramic industry, other high temperature waste heat recovery applications are considered in the paper, such as in concrete and steel production, which could have a potential use in the ceramic industry. The state of the art technologies used in the ceramics industry are reviewed with a special interest in waste heat recovery from the ceramic process exhaust stacks and energy saving technologies.

Ceramic components are defined as non-organic, non-metallic materials that are consolidated using heat. The solidification of the ceramic based products takes place in a high temperature kiln, usually for a prolonged duration. However, the application of high temperature heat is by definition an energy intensive process. The energy consumption is reflected in the associated cost contribution, and there is a clear indication that a significant percentage of the total production costs is for energy consumption.

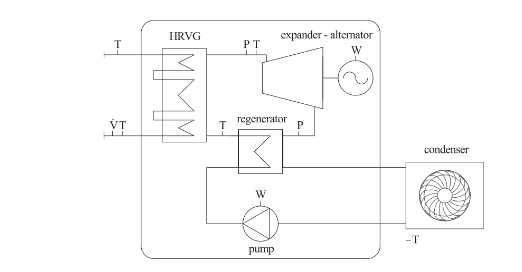

Schematic of an Organic Rankine Cycle

Studies on energy saving and the quality of ceramic products have highlighted that the implementation of energy saving technologies is crucial in response of the worldwide energy crisis and environmental issues but also for product quality and cost reduction. *

The European ceramics sector is divided in two different sectors: “traditional ceramics” (wall and floor tiles, tableware and sanitaryware) and “advanced ceramics” (electronical ceramics, technical ceramics, and bio ceramics).

The tile ceramic industry is the largest sector within the traditional ceramics. Tile manufacture represents 75% of the total energy consumption; sanitaryware 15% and tableware 10%.

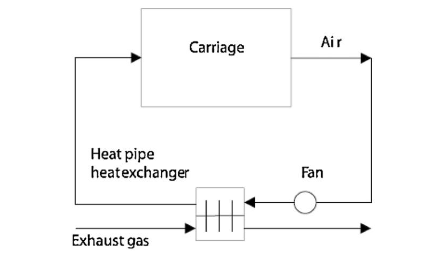

Schematic of a heat pipe based waste heat recovery system

The ceramic tile manufacturing process has four main stages: preparation of raw material, shaping, drying, and firing. A vast range of raw materials can be used by the ceramic industry to implement and expand the products range depending on the chosen product functionality. A combination of natural and synthetic materials can be used. Products such as wall and floor tiles, household ceramics and sanitaryware consist of aluminium silicates and clay-based materials.

The prepared raw materials are mixed in controlled proportions and homogenised to achieve chemical uniformity. Then the raw material is passed through a mechanical/hydraulic press. The shaping/forming stage is conducted when the material reaches the desired viscosity; typically, a softer (wetter) mix will require a higher heat energy during the drying stages which will eventually lead to higher drying shrinkage.

The shaping process is called the soft-mud process, the machine allow the mud to flow in a pre-sanded mould to obtain the shape. An external vibration can be applied to the mould to ensure a complete fitting and to consolidate the mix. When the raw material has achieved the desired shape of the mould, the part is send to the drying stage.

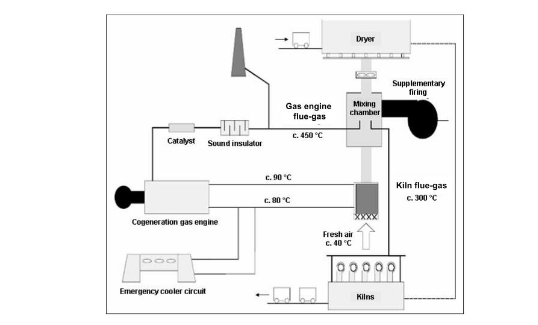

Traditionally, clay products were dried naturally by standing in the ambient air; usually during summertime, and left until dried. The modern ceramic industry needs a drying process that is efficient in both drying speed and low wastage. Heat for the drying air is mainly supplied by a combination of gas heaters and hot air recovered from the cooling zone of the firing kiln. The heat for drying air can be supplied by cogeneration or other fuels. The response of different materials depends on the drying process and this subsequently affects the drying times.

We can identify two different drying stages during this process, the first stage is an initial warming-up period in high humidity conditions followed by the main drying stage using hotter and drier air. The most difficult drying aspect is the removal of any residual water content left within the product.

The most common type of dryer is the tunnel dryer. These dryers consist of long tunnel structures with a line of carts loaded with the ceramic clay products. This continuous drying is achieved by high temperature air flowing within the tunnel. As heat is applied to the product, the humidity content within the tunnel will gradually increase. The length of the tunnel depends on the material and the moisture content in the product. Due to the high intensity heat requirements, approximately 26% of the total CO2 emissions are produced during the drying stage. This drying stage is crucial, in order to prepare the product for the firing stage.

The purpose of the firing stage is to increase the structural integrity of the product, for example the mechanical strength, abrasion resistance, dimensional stability, resistance to water and chemicals, and fire resistance.

The product is fired at a temperature which depends on the chemical composition of the ceramic clays, the typical firing range is 750ºC–1800ºC. The firing requires a significant amount of energy, and this is reflected in the contribution to emissions. Recent data suggest that the firing stage contributes 57% of the total CO2 emissions of the tile production process.

Terza lines supplied by SITI B&T

Tunnel kilns are commonly utilise in the ceramics industry for the firing stage. As for the drying stage, the products are placed on carts. The carts are moved through the kiln at set intervals.

Several optimisations have been tested and applied in the drying stage such as:-Optimisation of the recirculation of drying air: using more sophisticated ventilation techniques to control fundamental parameters such as relative humidity, temperature and flow rate improved the efficiency of the hot-air dryer.-

Waste Heat recovery: Clean hot air from the cooling exhaust of the firing kilns is available and can significantly improve the efficiency of the process. Waste heat recovery can provide up to 100% of potential energy saving for the drying process.-

Pulsed hot air: A periodically interrupted flow allows the use of higher drying air temperature; this solution allows enough time for the moisture to migrate from the centroid to the surface. These higher drying air temperatures allows a reduction of 40 min when compared with the process with a classic roller dryer.

Microwave drying: Microwave assisted drying has two obvious advantages. First of all, only the object is heated, whilst the chamber remains cool and so the energy to heat the drying chamber is saved. The microwave also heats the centre of the body and not only the surface; this promotes moisture migration to the surface. Water absorbs the microwave better than the raw materials, which considerably accelerate the drying. The use of microwave technology can significantly reduce the drying time (from 7 to 30 minutes, depending on the object/material).

This is an open access article distributed under the terms of the Creative Commons Attribution License 4.0