Smart line by SITI B&T

Smart line is SITI B&T’s end-of-line solution, combining sorting, packaging, and palletization. The plants are reliable, quick, easy to use, and modular for a versatile configuration.

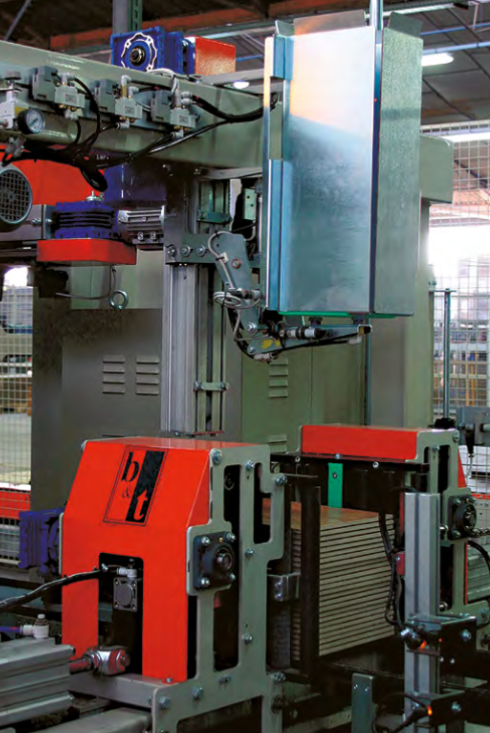

The line provides unique systems for product care as the stacker equipped with:

• System for adjusting the strength of contract between tile and belt resulting a reduction of wear of the belt;

• Double-column stackers with mechanical release and reset of the plate;

• Pre-stacking device with a side plate which enables the stacks to be formed in a more uniform way;

• Presetting for handling double stacks of small sizes in the same column;

• Servo-assisted mechanism for quick size change.

The line includes a single packaging machine,with quick size change and equipped with entirely built-in, centralized management of the printing heads. The entire sorting line is managed by easy and immediate management system and supervisor. The modular software program makes it straightforward to customise the machine and to install the units at the factory thanks to the use of connectors. The whole sorting, stacking and packaging line is managed by just one interface developed with Windows embedded platform, on a commercial PC and with colour touch screen monitor (LCD), with TFT technology (Thin Film Transistor).

This solution offers the following:

• Straightforward icons for intuitive machine control

• Online help function for each settable parameter

• Generation of production data statistics and graphs

• Alarm logs and relevant online help functions

• Easy viewing of the data by operators

• Integration with the company network

Simplicity of use of the electronic management system not just for the intuitive operator interface system with touch screen monitor, but also for the electronic/computerised components used and easily installed. There are no axes controllers or special boards.

• Complete integration with the LGV handling system to transfer and manage the data of the product and of the production statistics

• Ease of operation and maintenance. The machines can be accessed from both sides and the stackers are easy to replace. Just Wrap or just Cover packaging modes can be easily turned into the double mode version

On the inlet of each stacker that manages large sizes, there is a reject ejector for maximum tile size 600 by 600mm; tiles above this size that are to be rejected will be stacked.

Smart Line offers automated packing

For maximum tile size up to 900 by 600 mm, with the side measuring 600 parallel with the conveyor belts, the extraction system consists of four pneumatic ejectors by each stacker that all work on the same tile.

For maximum tile size up to 600 by 1,200mm or 900 by 1,200mm, with the side measuring 1200 parallel with the conveyor belts, the extraction system consists of a pair of four pneumatic ejectors by a pair of stackers which all work on the same tile. On the outlet of the stacker, there is a device that turns the stacks by 90° so that the package with the short side is parallel with the running direction.

An electric cabinet with conditioner and installed on the machine accommodates the commercial plc that manages the packaging unit and accessories. The operator interface is a cutting-edge commercial PC.

The packaging unit is just one machine, even for the WRAP and COVER double mode version, with hot melt application or cold melt application and rapid size change-over. It can also manage the text printer via a centralised and completely integrated system. For small sizes to be packed on a double stack, there is a card insertion unit, whereas for large sizes, the packaging unit comes in a special version.

The Wrap package can be sealed in the middle (std) with five spots of glue (symmetrical package); or at the side (optional) with four spots of glue (asymmetrical package). Whatever the initial configuration, it can be modified at any time; using a small kit, it can be turned into the requested packaging mode. This outstanding flexibility makes the sorting line independent of size based on the type of package.

The standard machine set up for automatic packaging consists of a carton magazine for cover packing (tray) and two carton magazines placed over each other for wrap packing. For both configurations, you can add another carton magazine in the special version.

The stack sent from the stacker is compacted and possibly divided in the case of large sizes. A device with suckers picks the package up from the magazine and places it in front of the stack to be packaged. A pusher pushes the stack through a tunnel with folders. The package is unloaded onto a conveyor belt built into the packaging machine on which an inkjet printer is installed, which prints the preset data on the box. Labelling and high definition printers can the be added.

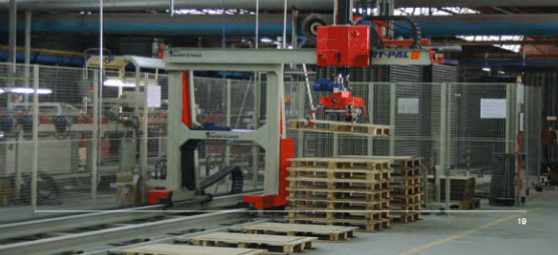

The palletizer is pre-arranged to manage a mixed flow of products, in terms of dimensions and type, and can manage different pick-up points. The pick-up gripper can be customised: by turning it from 0° to 270°, it can perform an independent single or double pick-up movement; it can also be equipped with a “pallet pick-up” or “in-between sheet” pick-up device.

Smart Line by SITI B&T: pallet control

The robot with Cartesian axes, with track on the ground, offers impressive configuration flexibility thanks to the track structure fitted on the ground on which the palletization unit runs; Parallel working area or just along the side of the structure; and four working axes.

The robot with Cartesian axes, with portal structure, offers smaller transverse footprint; possibility to palletize over the full area taken up by the structure; and multiple product in feed inlets, on any side. It is perfect handling of heavy loads because there are no components with overhanging movements.

Management is entrusted to just one interface developed with Windows embedded platform on a commercial PC with colour touch screen monitor (LCD), with TFT technology (Thin Film Transistor). This solution enables automatic and semi-automatic forming management; and display and updating of the state of the pallets and of the code queues, graphically and intuitively.

More at: http://www.sitibt.com/en/tiles-technologies/sorting-and-palletizing/smart-line/