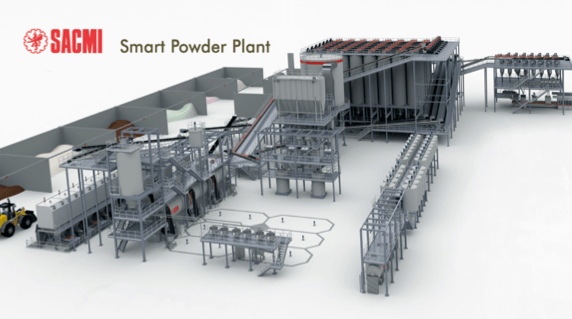

Smart Powder Plant is the new Industry 4.0 ceramic body preparation solution from Sacmi. It improves the performance and efficiency of body preparation lines, making them easier to run, boosting worker expertise, improving product stability, and allowing for predictive maintenance.

Smart Powder Plant by Sacmi

Thanks to new Industry 4.0 solutions for the continuous monitoring of key technological parameters, the raw material preparation department has lower waste, higher efficiency and improved finished product quality. It is an authentic Smart plant equipped with the MES Here system designed to control and coordinate all the machines.

The most innovative Smart Powder Plant solutions include:

• I-raw, which guides skid-steer loader drivers through raw material handling tasks by indicating the missions they need to perform. The system feeds missions to the skid-steer loader driver in pick-to-light mode by way of the display installed in the skid-steer loader cab, the flashing light on the picking bay and the source hopper status light;

• MCH100, which continuously monitors the moisture content of the raw materials fed to the mill. The key aspects of the system are microwave transmission, no contact with conveyed material and easy installation on existing conveyors/weighing units;

• BBT100, which continuously analyses all the parameters of the slip exiting the mill and uses feedback to adjust mill operation automatically;

• Belt conveyors equipped with systems for performing predictive maintenance.