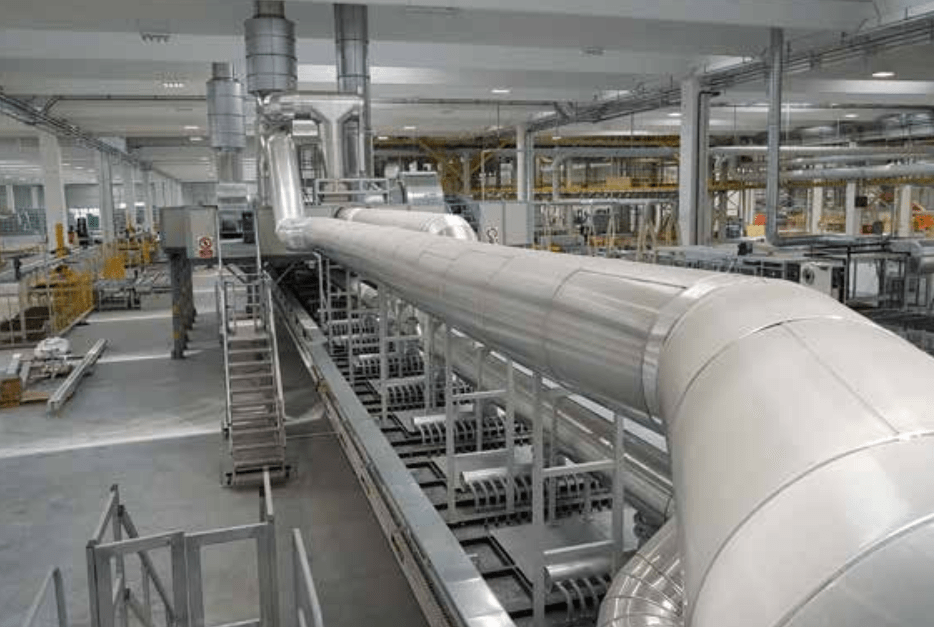

Sacmi kiln

The FMA/FMS single-layer roller kiln is: economical because it is well insulated, easily transported and assembled, and can be precision-adjusted; flexible because burners are both numerous and versatile and because control systems are fast-acting; productive because consumption is optimised; of outstanding quality, because firing curves are precise, the drive system is reliable and heat distribution is homogeneous; safe because it complies with CEN EN 746-1 and CEN EN 746-2 standards.

The FMA kiln uses a modulated air system and the FMS, a fixed air system. The combustion systems used are modulated air on the FMA and fixed air on the FMS. On the FMS kiln, the temperature in the different zones is controlled by modulating the gas, while the quantity of air delivered to the burners remains constant under all operating conditions.

The combustion system in the FMA kiln is modulated gas and air with a ratio correction. This system ensures the greatest flexibility, production output and burners a ring is installed for air and another for gas. A modulating valve is installed on the air supply, which increases or reduces the flow of air to the burners, depending on the temperature. Downstream of this valve there is a copper tube which, by means of a pneumatic signal, controls a low regulator located on the supply to the associated gas ring. In this way, by increasing or reducing the temperature, the air to gas ratio remains optimal. Another modulating valve is installed on the gas circuit that enables the air/gas ratio to be varied based on the product to be fired. Changing the firing curve and the cycle and raising or lowering the level of oxidation in the channel is managed automatically by the system.

The number of inverter controlled gear motors on the system varies according to kiln length. Each gear motor controls an average of three modules in the firing zone and a maximum of four modules in the cooling zones. Extraction and re-insertion of the rollers is, thanks to a special device, very easy and gives the advantage of simplifying work even while the material is being fed through the kiln.

It is also possible for each roller to rotate at a different speed from those before or after it (SACMI Progressive-Synchro Anti-Distortion patent). This special kinematic solution removes the synchronism condition on the drive system and does so without generating the problem of accelerated roller dirtying.

Sacmi is particularly conscious of the need for safety and has installed an emergency pull-cord along the length of the drive side of the kiln. When the cord is pulled the drive mechanisms are shut down immediately. Just as kilns have steadily evolved over the years, so has one of its most essential components – the roller. Today, most kiln rollers are of the ceramic type. Over time they have become more and more specialised, their characteristics reflecting the exact conditions in the kiln zones where they are installed.

Sacmi generally uses rollers with a high modulus of elasticity from the very first drive units onwards, thus ensuring that the product arrives in the firing zone in as orderly a way as possible. This prevents damage caused by bumping and pushing and a consequent drop in the level of output quality. Also available – on request – is the Vector, a patented “corrector” roller that, by maintaining an orderly feed of the pieces, eliminates the phenomenon of localised deformation on highly vitrified products.

The single-layer kiln is divided into pre-fabricated modules that make transport and assembly easier. No foundation works need to be carried out. All that is necessary is a flat floor on which to position the kiln.

The special frame design improves access to the roller holder bricks zone so that roller flocking tasks can be carried out. After the rapid cooling fan, the main manifold splits into two – an upper and a lower: this arrangement provides two independent air feeds to the blowers placed below and above the rollers. Two manual butterfly-type valves are installed on the two manifolds to regulate upper and lower blowing as required. The system can also be automated to manage any gaps in the production flow.

Sacmi kiln burners

In very large kilns silicon carbide blowers replace the first upper metal ones. On machines for medium-to-high output rates an air-air exchanger above the rollers in the rapid cooling zone allows part of the heat extracted from the product to be recovered and re-used to preheat the combustion air. It is also possible, depending on the specific technological process, to exclude the exchanger completely or partially by activating a by-pass valve.

A series of stainless steel pipes in the upper section of the slow cooling modules draws in ambient air. As this air passes through the ducts it extracts heat from the material progressively and evenly. A butterfly valve controlled automatically by the panel allows regulation of the intake rate through the general manifold so as to achieve the desired in-zone temperature. Depending on the configuration, the regulation can be sub-divided into two or more independent zones.

The FMA/FMS series kilns can be equipped with different heat recovery systems, recycling the air used to cool the material as combustion air. There are three heat recovery systems available depending on the needs of the client: the BSR, MDR and SPR systems.

BSR (low-heated combustion air) The air taken from the outside passes through a heat exchanger located in the rapid cooling zone before being sent to the burners at a temperature of about 100°C. By extracting heat from the Rapid Cooling system, the heat exchanger also reduces the area required for cooling the material.

MDR (medium-heated combustion air) Air collected from the slow and final cooling zones and expelled through the chimney at a temperature of 100-120°C is intercepted, sent to the heat exchanger in the rapid cooling zone and then used as combustion air.

SPR (super-heated combustion air) The system involves doubling up of the fan that collects air from the indirect and the final cooling. The indirect cooling air and the air from the first part of the final cooling is directed to the first fan: blending the two lines makes air available at a temperature of 140-160°C. The combustion air fan draws the necessary airflow from this chimney and sends it to the heat exchanger located within the rapid cooling zone.

The kiln’s electrical panel provides the centralised control and command of all process quantities: Temperature, pressure, product speed rate, deviation from preset values, etc. The panel is equipped with the HERCULES control system.

This system consists of a supervisory unit and an operator interface with an industrial PC, a high-resolution colour graphics monitor with a touchscreen system, and a multiple PLC system for managing the safety devices, movement, thermal part, emergency operator panel, graphics printer, keyboard and mouse. The Hercules software has the following functions: it regulates and displays the temperatures of the various areas of the kiln, monitors and adjusts the speed of the production line, oversees turning the kiln on and off, provides the production parameters such as the cycle and the daily, monthly and weekly production, and monitors the consumption of fuel and electrical power.It also supplies data on more than one hundred firing curves, displays any active alarms and stores them in memory along with all the control parameters, presides over the automatic change and advancement of the firing curves, and displays the progress of the material in the kiln in order to adapt the process parameters.

In addition to the standard configuration which has a single power panel that houses the supervision PC, an optional configuration is available in which the PC is housed inside a remote control panel. For both configurations a system can be set up with two PCs that enable process control and data management to be carried out separately.

The system is specially designed to keep the fast and slow cooling areas as similar as possible in the event of gaps in production, in order to prevent breakage and deformation of the material arriving after the gap.

This feature assures flatness defects and breakage do not occur.The system includes: motorized valves and burners in the fast cooling zone and a motorized hood in the last module of the slow cooling section with a transducer and pressure monitoring in the channel.

The RVE system is designed to recover hot air from the final cooling flues of the kiln for use idryers, spray dryers or other equipment. The RVE system can be constructed in different layouts to fully exploit the air flow available. The entire system is controlled by an inverter, pressure transducer and software that interfaces the kiln’s cabinet and the components to which the recovered air is supplied.