Ferrari & Cigarini specialises in the design and manufacture of machines and plants for the tile manufacturing industry.

Ferrari & Cigarini Setsu Shinobu Ito Tide

Since 1988, when the first cutting machines were designed for single-fired, double-fired and porcelain stoneware tiles, constant research to find solutions for problems in processing special pieces has led the company from Maranello to design and produce specialised plants for the production of mosaic pieces, strips, skirting tiles, bull-nose and steps and completely automated feeding systems (also thanks to the use of robot stations) and unpacking systems for grinding, honing and lapping lines. It is indeed in the unwrapping sector that Ferrari & Cigarini holds the international patent of the unwrap system.

Thanks to many years of experience in the design and production of mechanical equipment and industrial automated systems, Ferrari & Cigarini has also currently expanded its production range towards the sector of marble and stone, through the design of machinery for recovering waste material and for subsequently turning it into strip tiles, decorative in-fills, plinths, frames and special profiles.

Also strong in the building material sector thanks to the production of machinery for cutting strips, corner pieces and hollow flat tiles for ventilated facades, Ferrari & Cigarini also makes its mark in the glass sector and creates shuttles and automatic robots for feeding the cutting benches and the work stations.

Automatic machine for cuts, antislip incisions, pre-cut and special cut such as: mosaic, triangle, rombus. Able to work with marble, granite, gres porcellanato, agglomerated, brick and single-double firing. The TMC2 system offers many advantages such as:-

• On the shaft of motor-spindle it is possible to mount till 4 cutting blades, divided by spacers and flanges, in order to obtain different sizes and multiple cuts contemporarly.

• The motorized conveyor belt improves the working quality and allows the production of pieces continuously.

• The guide positioned on motor side and the pressor bar guarantee, during working phase, a strong stability and an high level of finishing piece.

• All adjustments are facilitated by the use of handwheels and they do not require the use of tools.

• A lateral roller allows to lay the big sizes to be worked

– TMC2 has more speed of material progress and it allows to make cut, pre-cut and cut.

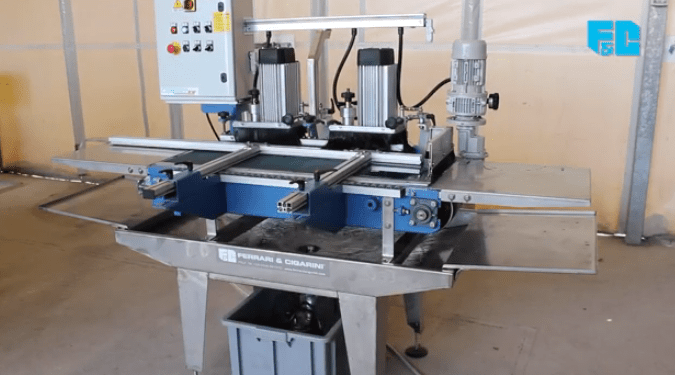

Automatic machine with two motor spindles to work with to different grinding wheels contemporary reducing the working time. It is possible to make half bullnose, jolly, bevel, and marble, granite, mono-firing and agglomerate working. The MPC2 system also has many advantages including:-

MPC2 by Ferrari & Cigarini

• Two motor spindles allow to work with two different wheels reducing the working time.

• The motorized conveyor belt improves the working quality and allows the production of pieces continuously.

• The guide positioned on motor side and the pressure bar guarantee, during working phase, a strong stability and an high level of finishing piece.

• All adjustments are facilitated by the use of hand-wheels and they do not require the use of tools.

• A lateral roller allows to lay the big sizes to be worked.

More at: https://www.ferrariecigarini.com/en/